Part I:

IRONPROS Field and Equipment Software Study finds field productivity/ticketing software the most common tech already adopted but GPS Fleet/Asset Management Software will see a substantial investment in years to come.

This article is part one of the FULL 2023 State of the Industry: Construction Technology Report, a four-part series that outlines the growing technology present in the construction industry, how contractors are currently embedding the technology into their workflow, the future of disruptive technology and the impact technology will have in acquiring a younger generation. Use the navigation bar below to maneuver through valuable industry insight:

- CURRENT ARTICLE - PART 1: IRONPROS Research Finds Field Productivity Software Most Significant Construction Technology Going into 2023

- DOWNLOAD THE PDF *Save to your desktop for easy reading & reference

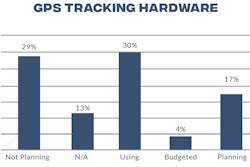

- PART 2: GPS-Asset Tracking Hardware, a Top 2023 Equipment Technology Priority

- PART 3: IRONPROS Study Reveals the Future of Disruptive Technology in Construction

- PART 4: Will Younger Construction Professionals Drive Technology Adoption?

- FULL 2023 State of the Industry: Construction Technology Report

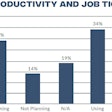

In this IRONPROS research report, we examine the priorities of contractors when it comes to deploying construction technology in the field. Field Productivity Software was the most significant technology respondents had either currently deployed or were planning and budgeting for. More contractors had in fact already adopted GPS-Enabled Asset Management software, but based on these results, it will soon be eclipsed in its adoption rate by field productivity tools that handle job ticketing, materials and equipment tracking and even time and productivity reporting in the field.

During 2022, IRONPROS surveyed almost 200 construction professionals on their current usage of or plans to use various technologies in the construction industry. These construction technology product categories may have components that are accessed in the back office by administration, managerial and executive staffers, but are designed primarily to extend enterprise software into the field.

This leap has been enabled by mobile technology that leverages smart phones and other devices not only to enable field employees to interact with an application, but to harness phone features like geolocation and cameras. Other specialized devices like wearables and drones may similarly use a mobile device or hardware as much as an Internet of Things (IoT) sensor to monitor production or capture data, providing location-specific context for digital workflows.

The 2022 IRONPROS study addressed this adoption curve and plans to invest in:

- Field Productivity/Job Ticketing

- GPS-Enabled Fleet/Asset Management

- Safety Software/Wearables

- Photogrammetry

- CMMS/Equipment Maintenance Technology

Looking at where each product is on this adoption curve, we see that:

- Usage of two categories, CMMS/Equipment Maintenance Technology and Field Productivity/Job Ticketing could double in size within the next two to three years.

- Among the product categories studied, more respondents were in the planning stages on adopting Field Productivity/Job Ticketing at almost 30%.

- Photogrammetry is in a statistical dead heat to also double in size, and given advancements in technology now coming to market could rapidly become even more appealing to contractors.

- GPS Fleet and Asset Management is the most mature product of those studied, and as the capabilities of these products expand and as vendors make integrations with other enterprise technologies, this technology will become more powerful.

- Across all product categories, a fairly consistent percentage of respondents — around 5% — reported formally having budgeted for expenditures.

What is Field Productivity and Job Ticketing Software?

Managing a project from a desk chair is different from managing execution in the field. These construction technologies help assign and ensure completion of work packages on site. These products vary in scope depending on what part of the construction market they are addressing. Some started life as field service management products, designed to manage fleets of technicians and later adding functionality required for project management and assignment of interdependent tasks on a construction site. Others include extensive integration with equipment telematics and can assign, manage and even report both equipment and crew production data.

Related Content

- Assignar Grows Field Productivity Footprint on Venture Investment

- Sage Field Operations Straddles Field Service and Construction

- EquipmentShare T3 Transforms Construction Equipment and Field Operations

- Clockshark Offers Widely Applicable Timekeeping

- B2W Augments Heavy Construction Estimating with Field Productivity

- STACK Field Collaboration Extends Estimating Platform

- HCSS Field Productivity Part of Broad Heavy Construction ERP Offering

See Related Products on IRONPROS

What is CMMS (Computerized Maintenance Management)?

Computerized maintenance management software (CMMS) or enterprise asset management (EAM) in construction may refer to software used to manage the built asset after handover as part of a maintenance service contract.

In situations like this, specifically in the case of industrial or productive assets as those in utilities (manufacturing or oil and gas), EAM may be the appropriate term given the executive-level functionality required to help executives balance cost of maintenance and operations against productivity and revenue.

CMMS is the term most often applied to technology that streamlines maintenance activities in a depot or shop environment, and may include tools for spare and repair parts, technician staffing and even support for advanced modalities like condition-based or prescriptive maintenance of construction equipment.

Sample Products:

- Tenna Is More than Tough

- Fleetio Offers Broad Fleet Management for Construction

- Asset Panda Expands into Construction

- HCSS Equipment360 Part of Broad Construction ERP

See Related Products on IRONPROS

What is Digital Site Survey Hardware?

Products in this category leverage lasers, LIDAR, 360-degree photography, GNSS or GPS signals to capture conditions on a site for a variety of purposes. These include supporting design, engineering or site planning, capturing quantities for estimating, tracking safety compliance or even progress reporting.

See Related Products on IRONPROS

What Are Construction Safety Software and Wearables?

Safety can be a feature of multiple construction software product categories. This construction software leads with safety practice enablement and reporting. Because a construction safety program is dependent on execution in the field to be executed, software used in this space will often collect data through the internet of things (IoT) from a wearable device or other sensors or digital site access points. While these products may primarily focus on communicating safety risks to field crews or tracking and automating safety compliance, some subcategories like robotic exoskeletons may enable an employee to perform work more easily without injury.

Related Content

Software solutions in this category may involve component parts, such as:

What is Construction Photogrammetry?

Photogrammetry is the technological discipline of capturing a 3-dimensional model of reality using photographic images, which in construction is often augmented with a building information model (BIM) or geographic information system (GIS).

Apart from light-based photography, photogrammetry in construction can also harness light detection and ranging (LiDAR), white-light digitizers and other technologies that generate a point cloud—a file containing x, y, z coordinates for discrete points in space. Photogrammetry can also involve creation of digital terrain models based on multiple aerial or satellite images.

Software vendors are now applying machine vision and artificial intelligence (AI) to this data to automate construction workflows including progress reporting.

Related Content

- Propeller Aero Gets Down and Dirty

- OpenSpace Extends Progress Reporting

- Constru Establishes North American Beachhead

- Avvir Augments Photogrammetry Tech with Services

- Hyundai Shows Platform Including Hi DETECT

- Hexagon AB Acquires Avvir

- SiteAware Uses Series B to Extend Solution

- StructionSite (now owned by DroneDeploy) Customer Part of Investment Round

Read our IRONPROS Photogrammetry Wiki to Learn More and See Related Products

----

FULL CONSTRUCTION TECHNOLOGY STUDY:

Navigate to your next insightful report:

- CURRENT ARTICLE - PART 1: IRONPROS Research Finds Field Productivity Software Most Significant Construction Technology Going into 2023

- DOWNLOAD THE PDF *Save to your desktop for easy reading & reference

- PART 2: GPS-Asset Tracking Hardware, a Top 2023 Equipment Technology Priority

- PART 3: IRONPROS Study Reveals the Future of Disruptive Technology in Construction

- PART 4: Will Younger Construction Professionals Drive Technology Adoption?

- FULL 2023 State of the Industry: Construction Technology Report