Off-site, industrialized construction, modern methods of construction, prefabrication, factory-built—all of these terms are usually applied to projects where the substantial parts of construction are executed in a separate shop-based environment. VC firms are investing in companies and technologies that purport to revolutionize the industry with exotic approaches to modularity, usually with a goal of solving major societal problems like the housing crisis.

But when IRONPROS caught up with Symetri USA Executive Vice President of Global Strategy Amy Marks, she refocused the conversation on the part of the industry where off-site fabrication is most common—mechanical, electrical and plumbing (MEP) contracting. She and Symetri Global Product Manager Edward LaRiviere also shared details on Naviate MEP and Fabrication, their Autodesk Revit bolt-on that is offered in an edition to streamline offsite fab for MEP contractors. This solution is aimed less at attempts to broadly transform construction, and more on helping individual contractors narrowly transform their operations to yield a financial return for their business.

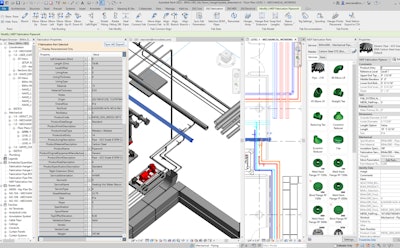

MEP Prefabrication Software

“The majority of the prefabrication that's done on this planet is above the ceilings, behind the walls and underground,” Marks said. “It is literally the mechanical, electrical and plumbing systems that are fabricated more than anything else. Unfortunately, in journalism, most people love to talk about the big sexy boxes that are stacked on one another, volumetric modular. But that is such a tiny fragment—about 5%. But when you're talking about the majority of MEP contractors, and the top 600 MEP contractors in the United States, 70-95% of what they're making comes out of their fab shops.”

Mechanical construction can represent 15% of construction cost, and electrical another 10%, according to one study. This percentage may be much higher in complex projects like hospitals, data centers and life sciences facilities where mechanicals in the headwalls and distribution racks running through corridors represent a substantial investment.

“Our product, Naviate, enables those contractors to actually understand how to develop and design and fabricate components in a more efficient way,” Marks said. “They can track things out to the field in a more efficient way. They can reuse those component kits and actually evolve them so that the designers can consume those instead of having to redraw them every time.”

As an Autodesk partner, Symetri has created independent software vendor (ISV) solutions that extend Autodesk REVIT and the Autodesk Construction Cloud. ISV solutions, often built inside of a large software vendor’s development platform, make broad solutions like Autodesk REVIT more usable for specific purposes, in this case offsite mechanical fabrication.

“I came here from Autodesk in order to connect design to fabrication and fabrication to the field,” Marks, who had served at the VP level at Autodesk, said. “There is a gap that currently exists in the Autodesk tools, and they would be the first ones to actually admit that. These needs can be filled by the ecosystem of platform partners like Symetri with Naviate.”

Naviate and Symetri’s other offerings are built on Autodesk Platform Services, formerly called Forge. Two of their offerings, like Naviate Simple BIM and Naviate Correspondence, will look familiar to customers of Newforma, another Autodesk partner with analogous products. Naviate for Revit, however, has deep hooks into Autodesk Construction Cloud for an entirely different use case, particularly when paired in a combined solution with Allied BIM. In 2023, Symetri and Allied BIM announced the Naviate Fabrication Bundle powered by Allied BIM.

Symetri partnered with Allied BIM to do full model to machine workflow giving actual feedback back to Revit users from the shop in real-time.

Spreading cuts across multiple assemblies, Allied BIM’s expansive cut profiles allows users to make sure their most dangerous cuts are the easiest and safest to cut while minimizing waste. All while minimizing waste and leveraging the actual machines in fabrication shop. So, from one Revit model it shares and adjusts tolerances to any automated equipment in any fab shop - not just a single fab shop. That’s important to design build GCs. Allied BIM’s patent pending printer also prints directly in materials so you can scan it for BIM data, assembly and installation instructions. Users receive these benefits along with a bi-directional connection to Autodesk Construction Cloud.

Marks said their Naviate product came out of long experience working with MEP contractors.

“When you're consulting with MEP contractors that can't make the connection between Revit and Autodesk Construction Cloud, and you've come up with your own ways to do that, why not just make it a product and sell it, so that people can use it and it can have a product lifecycle,” Marks said. “All of these tools are informed by the users. We are on very quick sprints because we are listening to customers.”

One area of product growth is the addition of tooling and fabrication machines to ease and ensure manufacturability of industrialized pipe fitting, sheet metal, conduit, track and other components.

“More and more machines are being added so you can actually select them for the fabrication,” Marks said. “It's a constantly evolving set of tools with the partnership that we have, that's making this just a much more connected and seamless workflow.”

“We don't really care what machine we're mapping up against,” LaRiviere said. “Whatever you're using for prefab, whatever you're using for measurement either automated or manual, we've got something built out to start getting that information into the hands of the builders or vendors actually doing that prefab. We prefer to support that workflow with a paper free process, but we've also found it makes it a lot easier for them to understand what's going on if you can just rotate a 3D view, and really see what's happening down there. So that whole process from individual spools to being able to view those spools mapped out across an entire floor and dealing with that entire thing in a 3D space—I think that's really where we bring a lot of value.”

ROI in Revit and the Field

According to LaRiviere, Naviate drives value starting in Revit with speed gained during modeling.

“We've heard back from surveys that 20% of users save 80% or more, 50% of users save 40% or more of their time a week,” LaRiviere said. “On average, I’d say 90% of people are saving at bare minimum 20% of their time once they implement a set of tools to help them out. “

Another source of ROI according to LaRiviere is waste minimization.

“One customer did an implementation on a large data center, and they walked out of that data center with 98% less waste than the previous data center they had done without our solution being implemented,” LaRiviere said. “They actually walked out with just a milk crate full of cut ends.”

Naviate Pricing and Market

According to LaRiviere, Naviate and the Naviate Fabrication Bundle powered by Allied BIM can drive value for MEP contractors regardless of size, with success depending more on being on Revit and their desire to improve their design-fabricate-install workflows. LaRiviere said that Revit users already rely on components of Autodesk Construction Cloud, which means ACC should not be a barrier to Naviate or Allied BIM adoption.

“My ideal customer has been using Revit for some amount of time, and they have some machine automation down in their shop floor,” LaRiviere said. “But that's just the ideal—that’s not a requirement.”

BOTTOM LINE: Symetri and its products, including Naviate are of interest to MEP contractors, not only for the immediate win that can come from streamlined shop fabrication processes. As an Autodesk partner, Symetri is an example of the type of firm contractors can look to as they drive value from broad technology offerings like Autodesk Revit and the Autodesk Construction Cloud. Partners like Symetri can resell and implement Autodesk and other solutions, consult on implementation and ongoing digital transformation initiatives, and provide training and staff augmentation. Symetri might be a strong software ally for a variety of contractors beyond MEP—Naviate for instance comes in a Civil 3D edition as well, which streamlines public works projects with functionality for mapping, roadway, landscape elevation, traffic symbols and more. In construction, as contractors delve into digitization and automation perhaps for the first time, the partner network of a major technology vendor like Autodesk will be an important resource.