Millennials and Gen Z have been accustomed to buying everything – from cars to meals – with the click of a button. Businesses across industries are adapting to this new way of transacting. The heavy building materials space values close partnerships between supplier and customer, but sometimes enhancing partnerships requires delivering touchless customer experiences that empower buyers with visibility and contactless workflows.

So, what does an empowered customer look like in the building materials world? Let’s compare the customer experience to one that I like to enjoy multiple times a week – the experience I get when using UberEats. Why do I love UberEats so much? Convenience. When I’m hungry, I just open the application on this supercomputer that I call my phone, and I can place my order instantly as opposed to calling and having to speak with someone. Once my order is placed, I can open the app to keep tabs on the order and check delivery status. If there are issues with the order, I can make adjustments to my plans based on when the food will be delivered or if the order can’t be fulfilled the way that I ordered it, I can prepare myself for that. I can opt to have the food delivered at the doorstep without having to communicate with anyone, and I receive confirmation that the order is here and ready to eat. I don’t have to pay anyone directly for the food, I just put my credit card information in and purchase the meal. Everyone involved – from contracted restaurants to the transportation providers – everyone has visibility into what’s going on with my food order.

First, We Must Ask: Do I Really Need Food?

The first step is having hunger – a need to fill. People typically don’t pick up their phones and order food from any food delivery service if they are not planning to consume food in the near future. Much like ordering food based on hunger, ready mix producers should only be ordering materials when they are needed. Knowing when you’re hungry and when you’re running low on inventory is like comparing apples to oranges. One is a physiological sensation while the other requires a lot more effort and historically, a lot of manual processes to figure out. Typically, figuring out inventory levels requires hours of the Batch Operator and/or Plant Manager’s time entering inventory information into their automated batching system. In fact, many ready mix operations rarely keep track of their inventory levels as well as they could, chalking it up as a “cost of doing business.” But what exactly can that cost them?

Say the Plant Manager has the “just keep it full” mentality and orders unnecessary material – that can put that operation at risk. If the truck shows up to deliver material when silos are full, then that order gets rerouted to another plant (assuming there’s even another plant to send the order to). If the cement pig is full, then that truck sits in the yard and waits until there is space in the cement pig; meaning, that truck can’t grab more orders, and you pay extra for the time that that truck is doing nothing. The system simply doesn’t work.

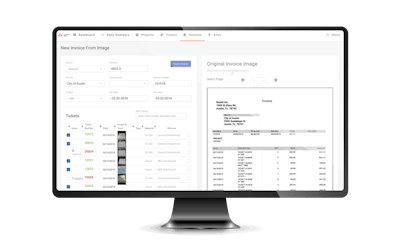

Many businesses are finding better business returns with systems that digitize each inbound ticket to automatically update inventory levels. There is less effort and friction to determine when and how much material is needed, and you get an accurate picture of what the inventory levels look like for each plant. A solution like this would translate into a big impact for a business that hasn’t kept track of inventory levels – not because they didn’t want to, but because they didn’t have the right tools. With systems like this, companies are empowered with better financial controls than ever before and have the foundation for a more modern supply chain. Their operational aspects have better visibility into how much material is there, and they are going to understand how much of the material is needed and when it is needed. Kind of like knowing whether you need a big meal or just a snack, right?

I’ve Ordered…How Much Longer?

Part of the reason why I continue to use UberEats is because it provides visibility into how the order is proceeding, from the time it’s entered into the order management system to final delivery at my doorstep. Any time there’s an exception with the order – let’s say the order was supposed to be delivered within 30 minutes, but the traffic on the interstate added 14 minutes to the route – I’m notified and can plan accordingly. Someone who is purchasing critical path materials for their job needs to be updated on the status of their ready mix concrete orders in the same way.

In the heavy building materials world, we have strict timelines we must meet to complete the job on time, in spec, and within budget. If something happens to delay a delivery from a supplier, the entire day’s schedule can be thrown off. How do you feel when your order from UberEats does not arrive when promised and you have no insight as to why? At a construction jobsite, late deliveries can cause problems more severe than a frustrated consumer with a grumbling belly. If materials are late, it creates a ripple effect that affects every single jobsite activity and significantly adds to project costs. To avoid this, leading ready mix producers are turning to cloud-enabled dispatching solutions to plan, place, and track orders, any time and any place. The ability to do so can reduce those risks and enable better transparency.

What’s the Value in Empowering Customers to Self-Serve?

A big reason why I love UberEats is the delivery updates and tracking information that allow me to keep tabs in real time where the order is and when it will arrive. I can self-serve through a simple interface that lets me see the status of the order, and I can receive customer support if needed. Similarly, the ability to share truck locations and ETAs provides visibility from dispatch to delivery and gives customers that same confidence and trust in knowing where their orders are and when they will arrive. This visibility gives materials buyers the insight to make data-informed decisions that improve planning and utilization, and dramatically cut down routine calls to the dispatch office to the tune of 30 percent.

It’s about empowerment. Empowering customers to monitor their orders, see trucks on roads and ETAs, and even view ticket details helps them to streamline their operations with the freedom that can only come from mobile apps - 24-hours a day, even if they’re not on the jobsite. Similar to the way that the UberEats app shares exactly what the driver picked up and when they did, ticket data shared through cloud-based tools informs buyers of when the driver picks up the materials and the exact quantities that are on the way to the job.

Convenience is the Secret Sauce

Let’s get back to where we started. Ultimately, where does my love for UberEats stem from? My love of CONVENIENCE. In a 2022 study from Shep Hyken, 70% of people said they’d pay more for a convenient experience, and 75% said they’d switch brands if they learned another was more convenient. If you want to enhance relationships with your customers and you aren’t delivering a convenient experience through cloud-based tools and self-serving options, your business will eventually perish against another business that does.