In choosing gloves for winter work, factors should focus on comfort, weather protection, conditions and functionality – all of which leads to great work efficiency. Construction workers should consider the temperature range of the worksite and focus on the lowest temperature in that range when making glove selections. The choice of work gloves should ensure they have sufficient insulation for the anticipated weather conditions.

Proper insulation can be found in such materials as fleece, Thinsulate, PrimaLoft and synthetics. Some gloves on the market come with a cold rating indicating under what temperatures the gloves can best operate.

Features and Functionality

For a winter weather work glove, the outer shell should be manufactured from material that is durable and abrasion-resistant, such as leather. Synthetic materials such as nylon or polyester offer a high level of water resistance and are lighter in weight. Rubber material is another option.

Keeping hands dry in harsh weather conditions call for choosing gloves manufactured from water-resistant or waterproof materials that will prevent moisture from reducing the gloves’ insulating properties.

Windproof gloves add an extra layer of warmth retention in windier conditions. Breathability is a key factor to prevent moisture buildup inside the gloves and prevent sweating as sweating hands can quickly get cold. Ventilation features and membranes in work gloves can provide breathability.

For optimal protection, consider cuff-style gloves that extend over the wrists and forearms or those with drawstrings that secure the gloves tightly around the wrist.

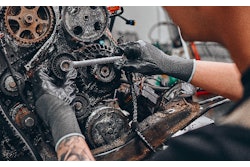

Lining material in the gloves can affect warmth and comfort. Moisture-wicking lining material that also is soft keeps hands dry and comfortable. Reinforced palms, knuckles and fingertips provide added protection. It’s essential the winter work gloves are designed with grip-enhancing materials for handling tools and equipment in harsh weather conditions. Textured palms or reinforced fingertips can provide grip protection.

Some work tasks require dexterity. In that case, while thicker gloves may provide more warmth, it can be necessary to choose gloves that enable fine motor skill work while also providing some measure of warmth. Workers who must use touchscreens while on the job should seek gloves with touchscreen compatible fingertips.

Those conducting work in low light conditions should consider gloves with reflective elements that will provide increased safety and visibility.

Learn More: Is the Milwaukee Tool High-Dexterity Polyurethane Dipped Gloves right for you?

Heated Gloves

Another option is to choose winter work gloves equipped with heating elements typically powered by batteries which generate heat to keep hands warm in cold jobsites. This story in IRONPROS outlines the benefits of heated gloves and factors to consider when choosing to use them.

These gloves are equipped with heating elements typically powered by rechargeable lithium-ion batteries which generate heat to keep hands warm. The heating elements are often crafted from carbon fiber or thin, flexible wires integrated into the heated gloves which generate and distribute heat throughout the glove, particularly in the areas of the fingers and back of the hands.

The outer shell of heated work gloves often is made from durable materials. Heated work gloves may feature temperature control.

Battery capacity and runtime depend on the specific gloves and settings and will typically last for several hours on a single charge. Those gloves with removable, replaceable battery packs enable those wearing them to swap them out as needed. The battery voltage is low enough as to not lead to electrical shock.

In addition to battery-heated gloves, some are heated through chemical activation, such as chemical air-activated hand warmers. These may be disposable.

Workers should check with the worksite’s safety manager to ensure that the selected gloves meet safety standards. The Occupational Safety and Health Administration notes that some factors influencing the selection of protective gloves for a workplace include the type of chemicals handled, the nature of contact (such as total immersion or splash), the duration of contact and the area requiring protection (hand only, forearm, arm).

Maintaining warmth is possible only through a proper size and fit. Construction workers should ensure top performance from winter work gloves by following the manufacturer’s cleaning and storage instructions.

While a visual inspection will help detect cuts or tears, a more thorough inspection can be conducted by filling the gloves with water and tightly rolling the cuff towards the fingers to help reveal any pinhole leaks that may compromise their performance.